Abstract

This paper will provide an insight into the new method in supply chain management, which is the elastic supply chain. This concept has become one of the most popular in the market during COVID-19 due to the numerous challenges that were faced by organisations and consumers at large. Different concepts were being tested in the market to enable agility as the COVID-19 pandemic was an unprecedented occurrence. There was an effort to collaborate with the suppliers as well as vendors to maximise the benefits from all available resources and minimize the quantities so as not to store any materials within the organisation and depend on the reliability of supply chain players. It is difficult to implement such a method because it will necessitate significant effort from all parties involved in such a chain. Such a method will undoubtedly necessitate a strong emphasis on the sustainability of supply chain operations, as the user will expect to receive the products on time to ensure operations run smoothly. ESC management is a borrowed concept from economics that has been evident in the implementation of operations during COVID-19. The methodology used in this paper is content analysis as it is a cross-sectional study done only during the COVID-19 pandemic. As a result, elasticity in the supply chain can help with competitiveness by streamlining operational functionalities. This is done through the support of different departments and the sustainable usage of resources along the supply chain.

Keywords: Resilience, real-time visibility, competitive supply chain, last-mile delivery, sustainable operations

Introduction

The elasticity term has been borrowed from the economic concept (Lim, 2019), which means a change of an economic variable in response to a change in another economic variable (CFI Education Inc, 2022). During the COVID-19 pandemic, there was an unprecedented cut-off of supplies and only the agile and resilient entities sailed through. This goes without saying that numerous companies shut down as they implemented an ordinary supply chain strategy in an extraordinary force majeure situation (Karasan et al., 2021). After an analysis of a few companies that managed to sail through, a unique trait was found which has led to this research that could be a new tactic that numerous other organisations can utilize to be well prepared in the future to safeguard their operations.

Elastic in the supply chain will save a lot of money for the end-user, which we refer here by saying end-user to the companies that have continuous projects as they do have different materials for different projects. Implementing elasticity for such organisations will maintain clear budgeting, reduce storing materials, and provide real-time visibility for the supply chain. All of that will be enhanced by technology that can lead to best practices in the whole supply chain. which can support implementing agile logistics in the organisation and support that technology being adopted within the organisation. Such a method can benefit the organisation in the long run and invest the liquidity of money in the right resources at the right time.

Problem Statements

When a supply chain is elastic, it is a responsive supply chain, which was the primary need during COVID-19. Had it been that numerous companies had tried to adopt this concept in advance, it would have had a significant impact on some companies which closed due to non-profitable operations (Milewski & Milewska, 2021). This has also enabled last mile delivery to be visible and possible as there was evasion of the virus in the process (Ranathunga et al., 2021), bringing innovative practices to meet demand. All of the reasons for more sustainable operations remain, as the mandate remains to manage smooth operations regardless of the situation or predicament at hand. The supply chain management concept is a viable strategic tool in solving logistics-related problems during the pandemic and in basic supply chain operations. Fixed contracts and one-time purchases have so many disadvantages which cost any organization money and time, which leads to delays in the process and improvement of the organization while others reach the top at an earlier time. This paper will review all the relevant literature to find out how to improve this sector in the logistics field.

Methodology

The study uses a methodology of document analysis. Document analysis is a type of qualitative research in which the researcher interprets documents to give a topic under evaluation voice and meaning. Coding content into themes and sub-themes is a component of document analysis. The main categories of documents used in this study are publicly accessible research papers in the field of researcher database and public access, such as those published in academic publications in the last seventeen years, between 2005 and 2022. However, only a very small number of 2005 documents that make reference to the fundamentals of the theory were chosen. These comprise information that is precise, accurate, and comprehensive, which will guarantee the validity and credibility of the results.

Literature Review

A review of the literature review on the phenomena will be done to give clarity on the applicability of these concepts in becoming a competitive entity in supply chain operations in a turbulent situation. The following reviews as shown in Table 1 have been selected carefully based on the literature review which was discussed and studied at the earliest time by different authors. The researcher chose the most pertinent points to support the desired outcome of this study.

Resilience in supply chain

In the latest supply chain resilience is recommended as it will save the organisation's cash flow, but it will require good communication with the suppliers. Coordination in the supply chain will lead to positive outcomes for the supply chain (Kumar & Anbanandam, 2020). To cope with the sensitivities of the supply chain, organisations must invest in and implement resilience (Konstantinou et al., 2021). Building resilience requires different strategies depending on the type of disruption, the position of the organisation within the supply chain, the effect of the disruption on the organisation and supply chain, and other related factors (Wang & Zhang, 2022). Some organisations implement resilience in crisis to avoid any operational impact (Kwak et al., 2018).

Real-time visibility

Good customer service will give the organisation clear visibility to the customers, which will allow them to rely on it to know the exact requirements even on a daily basis (Fields. R, 2021). Good communication from customers and vendors will lead to clear requirements and real-time visibility of the availability of products to the customers (Fields. R, 2021). Real-time visibility can be monitored by IoT (Internet of Things), which can easily be observed and implemented to the exact requirements in the supply chain, which will support implementing an elastic supply chain (Wanganoo & Shukla, 2020). When the quality and quantity of the information are reliable, then the customer and the company can plan their supply chain in a proper way and depend on that information (Alvarenga et al., 2022). Clear visibility of products will impact positively the resilience of the supply chain (Kumar & Anbanandam, 2020).

Competitive supply chain

Competitive supply chain can work with agile manufacturers as they are able to react quickly to gain business benefits (Kaviyani-Charati et al., 2022). The selection of the right pricing strategy can support the organisation in competing with others (Wang et al., 2016). The fixed price strategy may fail with competitors unless the price is not available from other competitors. In a crisis or inflation, competition decreases and it affects market spending, which will be reflected in the supply chain (Jiang et al., 2021). The competitive advantage will create challenges between the suppliers and manufacturers to produce the best product ever and make sure to perform their best performance to gain the opportunity to be the supplier for the organisation that requires the products or service (Dyahrini et al., 2021).

Last-mile delivery

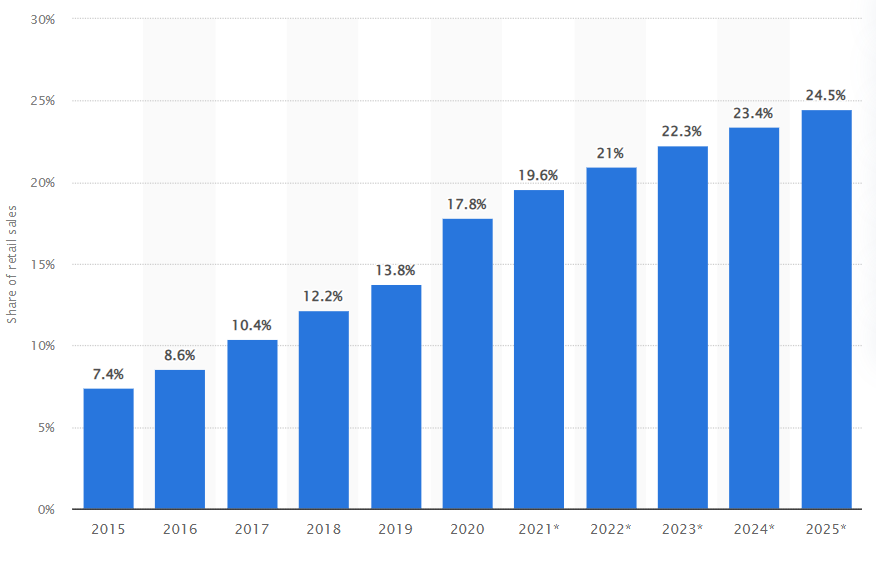

Last-mile delivery (LMD) is one of many countries' concerns nowadays, and it has many challenges as it affects consumer spending and customer satisfaction (Milewski & Milewska, 2021). The need for last-mile delivery (Alan, 2020) and the speed to find solutions for it, especially during the lockdown periods in many cities around the world (Milewski & Milewska, 2021). The need for LMD is not just because the cost of it is very high, as transportation itself produces over 24% of carbon dioxide (CO2) (IEA, 2020). Last-mile delivery is one of the trending topics in logistics around the world nowadays. Many organisations around the world are trying to create solutions for this concern. LMD is a subset of logistics, which is the world's primary field of operation (Belloso et al., 2019). The most expensive part of delivering products is the last mile (Ranathunga et al., 2021). LMD in smart cities needs to be advanced and meet the customer requirements (Mortara et al., 2020), as the demand for it has been increasing rapidly over time. In the below figure you can see the increase of the demand on the e-commerce as percentage of total retail sales worldwide from 2015 to 2020, with forecasts from 2021 to 2025 (Coppola, 2022).

According to the above figure 1, there is a significant increase in the demand for LMD that can be easily seen from more sales globally. The more online sales globally, the more demand for LMD, which will necessitate monitoring of the sustainable operations, not just the sustainable delivery.

Sustainable operations

Sustainability is the core topic of different organisations nowadays (Simoni et al., 2020). As an organisation becomes elastic in its own operations, it is paramount to consider the sustainability aspects of each function of the supply chain. There are different functions in the supply chain. The purpose of this paper is to support the finding of a sustainable solution that can be implemented in the supply chain, especially for LMD (IEA, 2020). That solution can be employed mostly in LMD as it is the most frequently used part in the supply chain and the most harmful part for the environment.

Elasticity in supply chain

According to Choi (2021), elasticity in the supply chain entails the adoption of a supply chain to the market and it is main characteristics are its products and the timely meeting of customer demands within its physical capabilities. The synergy of meeting supply and demand links it directly with the concept of elasticity. There can be either the elasticity of supply (in the case of when perfect competition exists) or the elasticity of the marginal cost curve (in the case of monopoly), which can showcase the ability of a supply chain to quickly adapt or retract in its operations.

Looking at the supply chain, the primary definition says it is the movement of goods from source to end user in value addition, that is, the transformation of raw materials to finished goods to meet customer demand (Jedliński, 2021) When investigating this concept, Choi (2021), noted that the elasticity of supply will address the responsiveness of the supply chain along with the costs of achieving that responsiveness. This therefore leads to a competitive advantage if high elasticity is advanced in the operations of the organisation.

Choi (2021) explains that high elasticity is encompassed by flexibility in manufacturers, shorter lead times, strategic uses of inventory, and operations below capacity with potential to expand quickly. Whereas in low elasticity, the contrary is true of long lead times, fixed manufacturing schedules, and operating near capacity with limited ability to expand or store inventory.

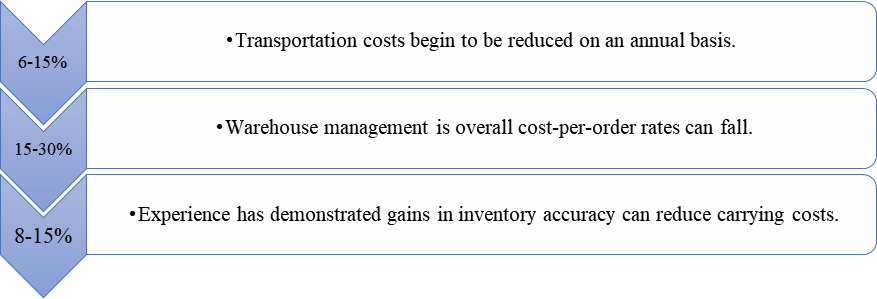

It is evident in the Figure 2 that when an organisation is highly elastic, they are competitive and readily open for expansion. It is when an organisation has the flexibility that there can be potential to proliferate responsiveness in dire, unanticipated situations. When the organisation becomes highly elastic, then survival and competitive advantage become a prospect.

Discussion

As we can see in the literature reviews, the elastic supply chain is new to the market, and it will require good market competition and availability in the local market or a quick response from the supplier whenever the products are not available locally. At the same time, communication between the vendor and the client will enhance the success of this method, which will lead to good savings and exact spending in any project that the organisation implements where no storage area is required, and inventory management is required. It is somehow close to the just in time (JIT) concept but different in nature. Resilience needs to be there from all parties in the supply chain to succeed in this method and gain the maximum benefit by implementing it. Assuring the availability of LMD will support the success of this method as it is one of the areas nowadays where researchers are working on finding a suitable solution for it to make it a reliable method to be used. Some organisations find a couple of solutions for it, but not for heavy trucks, which might require using the crowded city roads to deliver shipments whenever it is required. Elasticity in supply chains is a paramount tool as it assists some companies to be able to survive during this COVID-19 era. Novel ideas that came about due to adoption of this concept included: online ordering; efficient last mile delivery; consolidation of deliveries, leading to sustainable usage of the operational resources. Due to the limited number of employees that were employed to reduce the spread of the virus, rescheduling of work and capacity was mandatory by ministerial decree and also as a safety measure in the safeguarding of human lives. This enabled companies to adopt new methods of serving their customers, manufacturing products and, at the end, delivering products. This entailed managing the entire supply chain, which aided in the adoption of certain efficient software and communication lines, such as Zoom, Ms. Teams, and Virtual operational management tools. elasticity in supply chain operations proved to be a solution to logistics problems encountered during COVID-19. Some examples of the problems are incapacitation to manage operations, Lack of communication (internally or externally) as this is paramount in logistics operations, slow deliveries, wastage of resources as duplication of tasks was done prior.

Conclusions

Numerous technologies have been adopted during the COVID-19 pandemic. These are inclusive of the introduction of artificial intelligence and more agile software to adapt to the situation at hand. This concept of elasticity has been there for a long time but has not been used as often or used without mentioning this concept name. According to a McKinsey & Company report (2022), approximately 42% of companies weakened on average, while 28% soared on high. This was caused by numerous reasons, amongst which being adaptation to new business models, which focused on new digital experiences, products and services in response to the changes in consumer behaviors and needs; supply chain and operating model adjustments to manage risk, just to mention a few of the reasons. This thereby justifies the need for an elastic strategy as a tool in the supply chain to solve logistics-related issues. The companies that managed to prosper were the ones that proved resilient and adaptable in the adaptation of new strategies. This is the sole importance of this research to highlight the importance of using elastic supply chain management in promoting resilience and adaptability to new challenges that can come along the way. Recommendations for future research can be based on the microscopic investigation of the specific elastic supply chain management strategies that were used by these companies to maximise the benefits of these specific strategies. This would assist in circumventing some challenges that are faced in the logistics and supply chain management sectors. This research could also be done as a longitudinal study to check how other companies sailed through when some hardships similar to these occurred prior to assist the world in being resilient in the future.

Future Studies

Literature points out the elastic supply chain and the needs of LMD to support such an approach by various organisations for the benefit of understanding the current supply chain indicators and which factors will contribute towards a better supply chain strategy decision. Future studies can be done in artificial intelligence to find out the exact requirements for supply chains and the ways of delivering goods in an efficient and reliable way. That will support the forecast of demand and delivery for the future as well.

References

Alan, H. (2020). COVID-19 Pandemic and digitalization of service organizations: A trademark approach. Turkish Studies, 15(6), 31-47. DOI:

Alvarenga, M. Z., Oliveira, M. P. V. de, Zanquetto Filho, H., Desouza, K. C., & Ceryno, P. S. (2022). Is Your Supply Chain Ready for the Next Disruption? Building Resilient Chains. Revista de Administração de Empresas, 62(1), 1-17. DOI:

Belloso, J., Juan, A. A., & Faulin, J. (2019). An iterative biased‐randomized heuristic for the fleet size and mix vehicle‐routing problem with backhauls. International Transactions in Operational Research, 26(1), 289-301. DOI:

Coppola, D. (2022). Statista. https://www.statista.com/statistics/534123/e-commerce-share-of-retail-sales-worldwide/

CFI Education Inc. (2022). Retrieved on 15 May, 2022, from https://corporatefinanceinstitute.com/resources/knowledge/economics/elasticity/

Dyahrini, W., Mauludin, M. S., Ichsan, C., & Sinaga, O. (2021). Supply Chain Management, Competitive Advantage on Performance of SME Companies in Bandung, West Java. Review of International Geographical Education Online, 11(5), 820–828. https://doi-org.masader.idm.oclc.org/

Fields, R. (2021). Lack of Real-Time Visibility Still a Supply Chain Pain Point. MMR, 38(7), 15.

Choi, T.-M. (2021). Facing market disruptions: values of elastic logistics in service supply chains. International Journal of Production Research, 59(1), 286-300. DOI:

IEA. (2020) Transport sector CO2 emissions by mode in the sustainable development scenario, 2000-2030. https://www.iea.org/dataand-statistics/charts/transport-sector-co2-emissions-by-mode-in-the-sustainable-development-scenario-2000-2030

Jedliński, M. (2021). Unfulfilled advantages of the lean supply chain against contemporary threats: a sketch of changes in the scientific approach. Scientific Journals of The Maritime University of Szczecin, Zeszyty Naukowe Akademii Morskiej w Szczecinie, 67, 36–44.

Jiang, B., Rigobon, D., & Rigobon, R. (2021). From Just-in-Time, to Just-in-Case, to Just-in-Worst-Case: Simple Models of a Global Supply Chain under Uncertain Aggregate Shocks. IMF Economic Review, 70(1), 141-184. DOI:

Lim, J. (2019). How Modern Supply Chains Can Thrive with Elastic Logistics. Retrieved on 23 December, 2022, from https://logisym.org/how-modern-supply-chains-can-thrive-with-elastic-logistics-logisym-october-2019/

Kaviyani-Charati, M., Ghodsypour, S. H., & Hajiaghaei-Keshteli, M. (2022). Impact of adopting quick response and agility on supply chain competition with strategic customer behavior. Scientia Iranica. Transaction E, Industrial Engineering, 29(1), 387–411. https://doi-org.masader.idm.oclc.org/

Karasan, A., Ilbahar, E., Kaya, I., & Cebeci, B. (2021). Sectoral Prioritization of Industry 4.0 under Lean Supply Chain with an Integrated Fuzzy Decision-Making Approach: The Case of Turkey. 2021 IEEE 6th International Forum on Research and Technology for Society and Industry (RTSI), Research and Technology for Society and Industry (RTSI), 2021 IEEE 6th International Forum On, 441–445. DOI:

Konstantinou, C., Chatzoudes, D., & Chatzoglou, P. (2021). Supply Chain Resilience during the COVID-19 pandemic. 2021 IEEE International Conference on Technology and Entrepreneurship (ICTE), Technology and Entrepreneurship (ICTE), 2021 IEEE International Conference On, 1–6. DOI:

Kumar, S., & Anbanandam, R. (2020). Impact of risk management culture on supply chain resilience: An empirical study from Indian manufacturing industry. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability, 234(2), 246-259. DOI:

Kwak, D.-W., Seo, Y.-J., & Mason, R. (2018). Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. International Journal of Operations & Production Management, 38(1), 2-21. DOI:

McKinsey & Company. (2022). Strategic resilience during the COVID-19 crisis. https://www.mckinsey.com/capabilities/strategy-and-corporate-finance/our-insights/strategic-resilience-during-the-covid-19-crisis

Milewski, D., & Milewska, B. (2021). The Energy Efficiency of the Last Mile in the E-Commerce Distribution in the Context the COVID-19 Pandemic. Energies (19961073), 14(23), 7863. DOI:

Mortara, M., Ponte, D., & Zubaryeva, A. (2020). Towards the definition of a sustainable business model for last mile logistics: case study of city of Trento. In 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER) (pp. 1-7). IEEE. DOI:

Ranathunga, M. I. D., Wijayanayake, A. N., & Niwunhella, D. H. H. (2021). Solution approaches for combining first-mile pickup and last-mile delivery in an e-commerce logistic network: A systematic literature review. 2021 International Research Conference on Smart Computing and Systems Engineering (SCSE), Smart Computing and Systems Engineering (SCSE), 2021 International Research Conference On, 4, 267–275. DOI:

Simoni, M. D., Marcucci, E., Gatta, V., & Claudel, C. G. (2020). Potential last-mile impacts of crowdshipping services: a simulation-based evaluation. Transportation, 47(4), 1933–1954. DOI:

Wang, H., & Zhang, X. (2022). Research on Supply Chain Risk Transmission Mechanism Based on Improved SIRS Model. Mathematical Problems in Engineering (pp. 1–9). https://doi-org.masader.idm.oclc.org/

Wanganoo, L., & Shukla, V. K. (2020). Real-Time Data Monitoring in Cold Supply Chain Through NB- IoT. 2020 11th International Conference on Computing, Communication and Networking Technologies (ICCCNT), Computing, Communication and Networking Technologies (ICCCNT), 2020 11th International Conference On (pp. 1–6). https://doi-org.masader.idm.oclc.org/

Wang, Y.-Y., Sun, J., & Wang, J.-C. (2016). Equilibrium markup pricing strategies for the dominant retailers under supply chain to chain competition. International Journal of Production Research, 54(7), 2075–2092. https://doi-org.masader.idm.oclc.org/

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

18 August 2023

Article Doi

eBook ISBN

978-1-80296-963-4

Publisher

European Publisher

Volume

1

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1050

Subjects

Multi-disciplinary, Accounting, Finance, Economics, Business Management, Marketing, Entrepreneurship, Social Studies

Cite this article as:

Al Kaabi, S., Bathmanathan, V., & Lydia Ncube, M. Z. (2023). Elastic Supply Chain Management as Strategic Tool in Improving Global Logistics Service. In A. H. Jaaffar, S. Buniamin, N. R. A. Rahman, N. S. Othman, N. Mohammad, S. Kasavan, N. E. A. B. Mohamad, Z. M. Saad, F. A. Ghani, & N. I. N. Redzuan (Eds.), Accelerating Transformation towards Sustainable and Resilient Business: Lessons Learned from the COVID-19 Crisis, vol 1. European Proceedings of Finance and Economics (pp. 501-509). European Publisher. https://doi.org/10.15405/epfe.23081.44