Abstract

In this scientific paper, the possibility of using fuzzy logic methods and fuzzy equations in the construction of automated systems in the metallurgical industry to increase the efficiency of the plasma spraying technological complex is considered. The article discusses approaches to formalizing the assessment and management of the state of the control system of the plasma spraying installation, in which the main parameters are related to the operation of the plasmatron. An algorithm for automated control of a plasmatron using fuzzy logic methods is presented. The use of fuzzy logic makes it possible to use the accumulated knowledge of process control more effectively. In addition, such a method can contribute to improving the efficiency of controlling the process of applying protective coatings by the plasma method by automatically regulating the input parameters of the plasma installation. The formation of a controlled system will allow you to effectively connect technological equipment and inform.

Keywords: Fuzzy logic, control system, installation for applying protective coatings by plasma method

Introduction

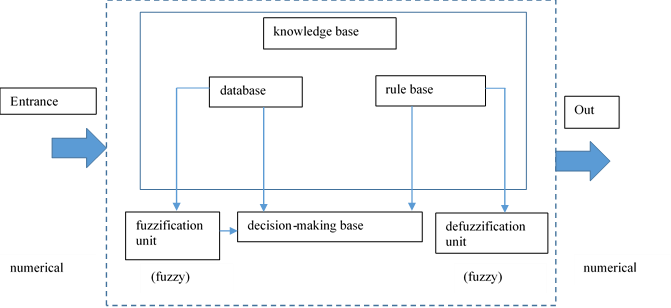

Currently, the use of fuzzy logic, the main feature of which is the ability to describe uncertainty by the formal apparatus of fuzzy sets (Asai et al., 1993; Glubokova, 2014), is widely noted in various industrial sectors: from applications in household appliances (smart robot vacuum cleaner, smart dishwasher, etc.) to the construction of road transport control systems, complex dynamic processes, etc. (Afanasyev & Filippov, 2010; Tugengold et al., 2017; Yasunobu & Hasegawa, 1987; Yarushkina et al., 2010). A hybrid combination of classical approaches and fuzzy logic is the most convenient way to build a control system in an environment of incomplete information and the whole process of fuzzy control consists of the following stages: fuzzification, the main process (development of fuzzy rules) and defuzzification (Afanasyev & Filippov, 2010; Stupina et al., 2008). The use of fuzzy logic makes it possible to use the accumulated knowledge of process control more effectively. In addition, such an approach can lead to an increase in the efficiency of controlling the process of applying protective coatings due to automatic control of input parameters (Milovidova, 2021).

Problem Statement

Creation of high-quality plasma coatings requires constant control and management over a significant number of process parameters of the control system of the plasma spraying installation (Taran et al., 2014). The formation of such a controlled system will effectively connect technological equipment and information technologies into a single technological structure for plasma application of heat-protective coatings with feedback and the possibility of automatic process control at different stages of the process. However, this approach complicates the operating conditions of the technological complex and leads to uncertainty in the complex dynamic system of production of an item by the plasma method.

The existing problems of controlling the technological process of creating high-quality heat-protective coatings of products by the plasma method are associated with taking into account in the process of operation of the plasma installation for monitoring and managing big data and such types of uncertainty as: errors of sensors measuring product parameters; accounting for all input parameters affecting the coating process; uncertain changes in assumptions made in the technological model of product production, etc.

Research Questions

The following questions were raised during the study:

- How to increase the efficiency of the plasma installation control in conditions of uncertainty of taking into account all input parameters affecting the plasma coating process?

- How to ensure the efficiency of big data management of a complex technological process: the plasma current, the vertical position of the plasma flow, the shape, density and temperature of the plasma to obtain materials with specified properties?

Purpose of the Study

The article discusses approaches to formalizing the assessment and management of the state of the control system of the plasma spraying installation, in which the main parameters are related to the operation of the plasmatron. An algorithm for automated control of a plasmatron using fuzzy logic methods has been developed.

Research Methods

When considering approaches to formalize the assessment and control of the state of elements and devices of the technological process for applying heat-protective coatings by the plasma method, the use of classical mathematical apparatus is limited. And when it is impossible to obtain reliable data on processes when solving complex problems associated with blurriness and inaccuracy, it is advisable to use hybrid approaches, including the architecture of fuzzy logic (Figure 1), proposed by the scientist Lofty Zadeh (1976, 1965) (Savchenko et al., 2021).

The corresponding representations of fuzzy sets (a Mamdani-type fuzzy model) can be applied to the assessment and management of the state of the control system of a plasma spraying installation (MSPSI):

where

X = {X 1, X 2,..., X N}

Y=R (X) – the set of input states of the spraying process variables;

Y = {Y 1, Y 2, ..., Y M} – set of control parameter values;

R is a fuzzy transformation operator in a state management system (Tugengold et al., 2017).

The control system of the plasma spraying installation includes the function of monitoring and controlling the process of coating with a plasmatron installed in the experimental installation.

The main control parameters of the MSPSI are associated with a plasmatron, a gas-discharge device used for applying plasma coatings. The plasma discharge is initiated and then maintained by a controlled change in current. We present the control of the state of the plasmatron as the i-th tool used in a certain p-m process in the operation of plasma application of a protective coating on products. The set of input variables X i that characterize the state of the i-th instrument in the system can be reflected as:

Xi = {Xiн, Xiо},

where

th tool corresponding to its state at the time of the start of the process;

is a set of operational parameters of theth tool corresponding to its state in the process of work (Tugengold et al., 2017).

The values of the main controlled parameters can be included in the set:

– duration of spraying, min,

is the current strength, A;

– tension, In;

– gas flow rate, m3/s;

– gas supply speed, rpm;

is the gas pressure, kN/m.

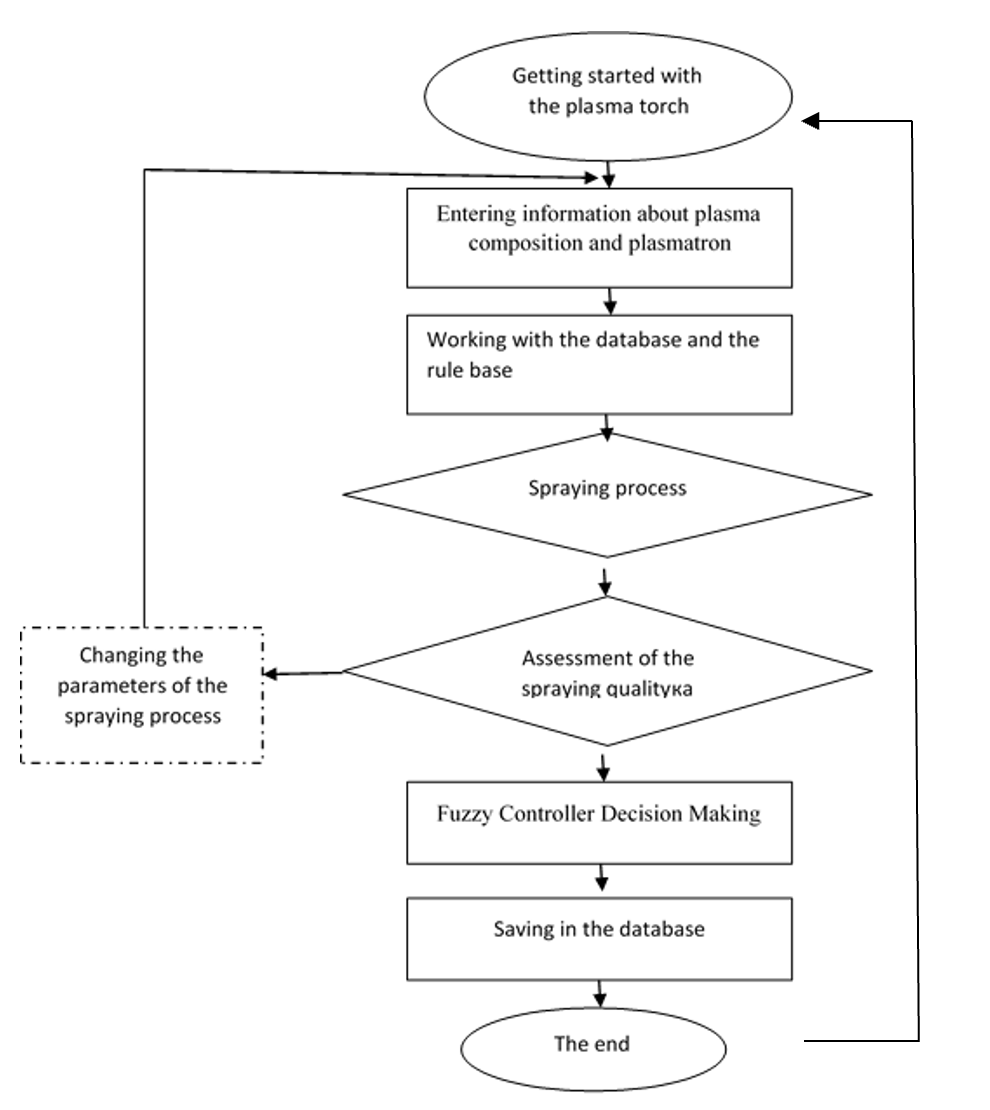

Figure 2 shows an approximate algorithm for the operation of the plasma torch control system in a plasma spraying installation.

The proposed approach is distinguished by the use of an extended structure that combines a fuzzy algorithm, workflow data collection, evaluation of results, a database of set values and a database of rules, an algorithm for configuring system parameters, which ultimately allows for the efficiency of managing large data of a complex technological process and obtaining material with specified properties. The designed MSPSI should provide control of the plasma current, control of the position (equilibrium) of the plasma flow vertically, control of the plasma shape, control of plasma density, control of plasma temperature.

Findings

The fuzzy logic method can be used to model and optimize processes in controlling the state of elements and devices of the technological process of applying heat-protective coatings by the plasma method in the metallurgical industry.

Conclusion

Thus, automation of control processes based on fuzzy logic methods will allow changing and setting the speed, temperature, density of the plasma jet, position and shape of the plasma flow, as well as other parameters of this complex technological process. This approach increases the control efficiency of the plasma installation in conditions of uncertainty of taking into account all input parameters affecting the plasma coating process, expands the range of capabilities of the plasma torch and increases the possible range of sprayed materials (metals, ceramics, etc.). Working out such dependencies and modeling them using fuzzy logic in the MSPSI can contribute to the creation of materials with specified properties.

Acknowledgments

The work was supported by the Ministry of Science and Higher Education of the Russian Federation (Grant No. 075-15-2022-1121).

References

Afanasyev, M. Y., & Filippov, A. N. (2010). Application of fuzzy logic methods in automated systems of technological preparation of production. Izvestia of higher educational institutions. Instrumentation, 53(6), 38-42.

Asai, K., Vatada, D., & Ivai, S. (1993). Applied fuzzy systems. Mir.

Glubokova, S. V. (2014). The use of neural networks in the problems of choosing methods for measuring deviations in the orientation of geometric elements of parts. Bulletin of MSTU "Stankin", 2(29), 63-67.

Milovidova, A. A. (2021). Decision support in production management in the mining industry: specialty 05.13.01 "System analysis, management and information processing (by industry)": abstract of the dissertation for the degree of Candidate of Technical Sciences. Volgograd, 20.

Savchenko, D. V., Reznikova, K. M., & Smyshlyaeva, A. A. (2021). Fuzzy logic and fuzzy information technologies. Waste and resources, 8(1), 1-10. DOI:

Stupina, A. A., Peremanskaya, S. N., Korpacheva, L. N., & Fedorova, A. V. (2008). Modeling of controlled processes: Lecture notes. Krasnoyarsk: Siberian Federal University, 158.

Taran, V. M., Lyasnikova, A. V., Markelova, O. A., & Dudareva, O. A. (2014). Automation of the process of plasma spraying of powder coatings on machine-building products. Bulletin of the Saratov State Technical University, 4, 1(77), 107-111.

Tugengold, A. K., Izyumov, A. I., Voloshin, R. N., & Solomykin, M. Y. (2017). Fuzzy control system of a multi-operation machine. Bulletin of the Don State Technical University, 2(89), 70-78. DOI:

Yarushkina, N. G., Perfilieva, I. G., & Afanasyeva, T. V. (2010). Integration of fuzzy models for time series analysis. Proceedings of the Samara Scientific Center of the Russian Academy of Sciences, 12(4-2), 506-509. EDN NDYIOH.

Yasunobu, S., & Hasegawa, T. (1987). Predictive fuzzy control and its applications for automatic container crane operation system. Tokyo: in Proc. 2nd. IFSA Congress.

Zadeh, L. A. (1965). Fuzzy sets. Information and control, 8(3), 338-353. DOI:

Zadeh, L. A. (1976). A fuzzy-algorithmic approach to the definition of complex or imprecise concepts. International Journal of Man-Machine Studies, 8(3), 249-291. DOI:

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License

About this article

Publication Date

27 February 2023

Article Doi

eBook ISBN

978-1-80296-960-3

Publisher

European Publisher

Volume

1

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-403

Subjects

Hybrid methods, modeling and optimization, complex systems, mathematical models, data mining, computational intelligence

Cite this article as:

Khramov, I. V., & Stupina, A. A. (2023). Fuzzy Logic in the Construction of Automated Systems in the Metallurgical Industry. In P. Stanimorovic, A. A. Stupina, E. Semenkin, & I. V. Kovalev (Eds.), Hybrid Methods of Modeling and Optimization in Complex Systems, vol 1. European Proceedings of Computers and Technology (pp. 71-76). European Publisher. https://doi.org/10.15405/epct.23021.9