Abstract

The annual world consumption of aluminum is growing by an average of 5-7%, and the aluminum market itself is inferior in volume only to the steel market. Therefore, research in the aluminum industry has always aroused an increased interest in the development of new methods and means to improve the efficiency and quality of the aluminum production process. The most important condition for the predictability of quality and, consequently, the declared performance characteristics of anodes is the stability of production processes during manufacture. Within a single production batch, all anodes must have similar characteristics. In addition, they must be made from a single batch of raw materials, since defects in parts that lead to a decrease in the potential and actual life of the part can be caused by impurities and other defects in the raw materials, as well as deviations (fluctuations) of the technological process. Deviations in the technological process in the conditions of automated production are highly likely to affect the entire manufactured batch. The problem of ensuring the stability of aluminum production by controlling the internal homogeneity of supplied batches of anodes was solved using an approach based on parametric optimization models.

Keywords: Anode, aluminum, homogeneous batch, cluster analysis

Introduction

Currently, the only industrial way to obtain pure aluminum is the electrolysis process. The feedstock is alumina, and the electrolyte is based on the cryolite-alumina system. In the electrolysis bath, when a voltage of 4.0-4.3 V is applied between the anode and cathode, alumina decomposes into aluminum and oxygen ions in the electrolyte. Aluminum anions are deposited on the cathode, forming a layer of liquid aluminum at the bottom of the cell. Electrolysis proceeds at a temperature of 950-970 °C (Han et al., 2020; Rozhnov et al., 2021).

Electrolysis in electrolyzers of all types takes place in a rectangular electrolysis bath with a casing made of steel sheet with a fireclay lining on the outside and fired coal blocks and coal wall slabs inside (the casing of small and sometimes medium-sized electrolyzers is made without a bottom). The carbon-lined bath is the cathode, and a suspended anode (self-sintering from carbon mass or baked coal) is introduced into the bath from above. Depending on the size of the bath, from 16 to 35 anodes and from 17 to 36 cathodes are provided.

The distance between the anode and cathode, the levels of metal and electrolyte, the shape of the working space, the temperature and composition of the melt, electrical parameters affect the efficiency of the aluminum electrolysis process. These indicators can be quickly adjusted by changing the interpole distance, as well as the consumption of alumina and aluminum fluoride loaded into the electrolysis bath (Rozhnov et al., 2021).

Statement of the Problem

To ensure the coordinated operation of the same type of system elements, it is important that they have very similar characteristics (be homogeneous). The homogeneity of the characteristics of the same elements of the system is achieved if these elements were made from the same batch of raw materials in the same production batch. Therefore, when completing critical system components with increased quality and reliability requirements, it is necessary to use appropriately selected components (Rozhnov et al., 2018).

One of the key materials in the production of aluminum is a baked anode (Bonel et al., 2019; Kevorkijan et al., 2019). The minimum change in the parameters of the anode entails significant fluctuations in the technical and economic parameters of the electrolysis process (the share of the baked anode in the cost of aluminum production is about 14 percent) (Andermann et al., 2019). Raw materials for the production of anodes are distinguished by the widest range of parameters of properties that determine the quality of products. Poor quality anodes not only increase aluminum production costs, but also increase greenhouse gas emissions. Consequently, the improvement of the production process for the production of anodes provides great economic prospects for the enterprise (Andermann et al., 2019; Kevorkijan et al., 2017).

In anodes, for example, there may be structural defects (for example, cracks) formed at the stage of forming "green" blocks or under poor firing conditions. The green anode is the non-baked aluminum plating anode. Since anodes are subjected to severe thermal attack in electrolyzers, their resistance to cracking is of great importance. Failure of the anode in the cell due to the appearance of cracks leads to serious undesirable side effects, as a result of which serious losses are possible.

The characteristics of the production batches of Aluminum Smelter Co of Nigeria (Alscon) were used as data (data sets) for research. This enterprise was built in 1997, and in 2006 became the property of RUSAL.

Research Questions

Organizational work plays an important role in ensuring the quality of supplied anodes. Of course, it is important to carefully select potential suppliers in order to exclude the possibility of getting low-quality (falsified) products.

In practice, the delivered batches of anodes may be heterogeneous, assembled from several production batches (i.e., they may actually be combined batches). Therefore, the results of the selective testing cannot be extended to the entire delivered prefabricated batch of components, unless there is a firm confidence that all anodes are made from the same raw material batch or that the variation in the parameters of various anodes is so small that it allows make a conclusion about the identity of their chemical composition and, as a consequence, the identity of the characteristics. Relatively small fluctuations in the manufacturing process can significantly change the performance of the anodes.

The control methods used are based on the control of the values of individual parameters of each anode. The control process is based on the assumption that anode failures that occur during operation are due to the physical and chemical degradation processes occurring in them that affect the measured parameters.

Identification of homogeneous batches of anodes requires the introduction of not only information technology, but also methods of data mining. The use of cluster analysis methods to identify homogeneous groups of anodes is important from the point of view of ensuring the reliability and continuous operation of the cell.

Modern methods of cluster analysis offer a wide choice of means for identifying groups that are heterogeneous in terms of the set of parameters. The most common of these methods is the k-means method (Arthur & Vassilvitskii, 2007). Algorithms that implement this method are global optimization algorithms and depend on the choice of initial values (averaged parameters of the centers of groups - clusters). At the same time, the method of identifying groups of products with different parameters should give reproducible results. The algorithms proposed in (Kazakovtsev et al., 2020; Rozhnov et al., 2019), which can become the basis of an automated system for identifying groups of products with different parameters, can significantly improve the accuracy of classification methods.

Purpose of the Study

The array of anode test data can be used to form special batches with increased requirements for the uniformity of characteristics within the batch (Rozhnov et al., 2018). Such special batches make it possible to protect the completed baths from inconsistencies in the anode operation time and failures of various kinds.

As mentioned earlier, depending on the size of the bath, from 16 to 35 anodes are provided in one electrolytic cell. Therefore, the task of dividing batches of green anodes into homogeneous ones before the firing process is one of the most important in the production of aluminum (Bonel et al., 2019; Kevorkijan et al., 2019; Kevorkijan et al., 2017).

Research Methods

The proposed method for improving the quality of anodes makes it possible to increase fault tolerance by rejecting products with hidden defects, which is achieved by preliminary selection of anodes. In addition, for highly reliable anodes that have passed the selection, it is possible to use reduced coefficients for basic failure rates, which will make it possible to refine the redundancy method (reduce the redundancy ratio or select its optimal form).

One of the promising areas in big data analytics is cluster analysis, the range of use of which is very wide and is used to solve problems in almost all areas of human life (Drezner & Hamacher, 2004; Rozhnov et al., 2019).

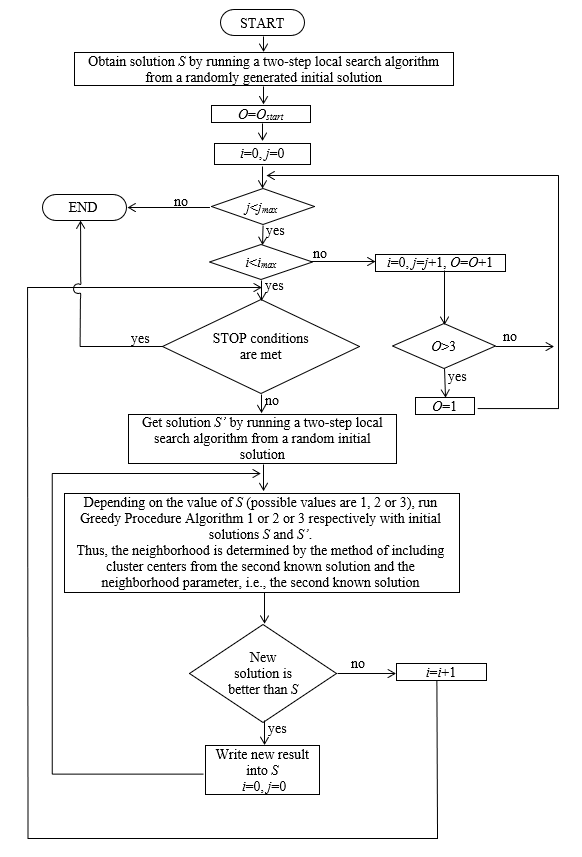

The combined application of the greedy heuristics method (Kazakovtsev et al., 2020; Rozhnov et al., 2019) with variable neighborhood search (VNS) algorithms (Kochetov et al., 2005; Hansen et al., 2001) for k-means (Drezner, 2015; MacQueen, 1967), k-medoid (García-López et al., 2002; Kazakovtsev & Rozhnov, 2020) problems and the CEM algorithm (Celeux & Govaert, 1992) was previously considered in detail in (Rozhnov et al., 2019; Kazakovtsev & Rozhnov, 2020). To increase the accuracy of calculations of automatic grouping algorithms, an approach was applied to the development of clustering algorithms based on parametric optimization models, with the combined use of search algorithms with alternating randomized neighborhoods and greedy agglomerative heuristic procedures (Rozhnov et al., 2019). The general scheme of this approach is presented in Figure 1.

GH-VNS (Greedy Heuristic in the Variable Neighborhood Search)

1: Run the two-step local search algorithm from a random initial solution to obtain solution. Assign=(number of the neighborhood type).

2:=0,=0 (the number of unsuccessful iterations in the current neighborhood and in total).

while<

while<

3:the STOP conditions are not met (the time limitation is not exceeded),run the two-step local search algorithm with the randomly chosen initial solution to obtain the solution.

repeat

4: Depending on value (values 1, 2, and 3 are allowed), run the Greedy Procedure 1, 2, or 3, respectively, with the initial solutions and.

the new solution is better than

store the new result to;=0;=0.

go to 6.

end loop

6:1.

end while

7:=0;=+1;=+1;>31.

end while

Findings and Results of Computational Experiments

When clustering data sets, each of the algorithms was run 30 times. According to the results of our experiments for each algorithm, the values of the objective function were calculated: the minimum value, the maximum value, the average value and the standard deviation. Algorithms k-means and j-means were run in multistart mode (table 1). The best values are in bold.

The following abbreviations are used in the table: GH-VNS is clustering algorithm developed using the approach under consideration, GA is genetic algorithm, GAGH+LS is GA with a greedy heuristic procedure with local search and real alphabet, GAF is GA with recombination of subsets of a fixed length (Drezner & Hamacher, 2004).

The splitting of a combined batch of anodes, consisting of two reference ones, using these methods gives very accurate results (Table 2).

Thus, the proposed methods are sufficient to solve our problem of identifying homogeneous batches of anodes, which, in turn, is a necessary step in the process of forming special batches of anodes (Rozhnov et al., 2019).

Conclusion

The results of computational experiments have shown that the GH-VNS algorithms developed using the presented approach (Figure 1) have more accurate (the value of the objective function is less than the average) and more stable (less the standard deviation of the objective function) indicators in comparison with the considered classical algorithms (k -means, j-means, PAM, CEM), as well as some genetic algorithms. Thus, the approach considered in this article can be applied to the problem of separating batches of green anodes into homogeneous ones before the firing process.

Acknowledgments

This work was supported by the Ministry of Science and Higher Education of the Russian Federation (Grant No.075-15-2022-1121).

References

Andermann, L. J., Jr., Mullins, A., Smyth, C., & Roscoe, C. (2019). Rheological Improvements in Alumina Industry Clarification Circuits. In C. Chesonis (Ed.), Light Metals. The Minerals, Metals & Materials Series (pp. 19-26). Springer, Cham. DOI:

Arthur, D., & Vassilvitskii, S. (2007). k-Means++: The Advantages of Careful Seeding. Proc. of the Eighteenth Annual ACM-SIAM Symp. on Discrete algorithms, ser. SODA '07, 1027-1035.

Bonel, L., Clerin, P., & Guillaumont, L. (2019). Environmental Friendly Transformation of the First and Oldest Alumina Refinery in the World. In C. Chesonis (Ed.), Light Metals. The Minerals, Metals & Materials Series (pp. 57-67). Springer, Cham. DOI:

Celeux, G., & Govaert, G. (1992). A classification EM algorithm for clustering and two stochastic versions. Computational Statistics & Data Analysis, 14(3), 315-332. DOI:

Drezner, Z. (2015). The fortified Weiszfeld algorithm for solving the Weber problem. IMA Journal of Management Mathematics, 26(1), 1-9. DOI:

Drezner, Z., & Hamacher, H. W. (Eds.). (2004). Facility location: applications and theory. Springer Science & Business Media. http://web.tecnico.ulisboa.pt/mcasquilho/compute/_scicomp/_location/ DreznerHamacher.pdf

García-López, F., Melián-Batista, B., Moreno-Pérez, J. A., & Moreno-Vega, J. M. (2002). The parallel variable neighborhood search for the p-median problem. Journal of Heuristics, 8(3), 375-388. DOI:

Han, X., Zhang, T., Lv, G., Pan, X., & Fu, D. (2020). A Review of Research on Alumina Extraction from High-Alumina Fly Ash and a New Method for Preparing Alumina by Electrotransformation. The Minerals, Metals & Materials Series (pp. 136-142). Springer, Cham. DOI:

Hansen, P., Mladenović, N., & Perez-Britos, D. (2001). Variable neighborhood decomposition search. Journal of Heuristics, 7(4), 335-350. DOI:

Kazakovtsev, L., Rozhnov, I., Popov, A., & Tovbis, E. (2020). Self-Adjusting Variable Neighborhood Search Algorithm for Near-Optimal k-Means Clustering. Computation, 8(4), 90. DOI:

Kazakovtsev, L. A., & Rozhnov, I. (2020). Application of Algorithms with Variable Greedy Heuristics for k-Medoids Problems. Informatica, 44(1). DOI:

Kevorkijan, V., Skledar, L., Degiampietro, M., Lesjak, I., & Krumpak, T. (2019). Comparative Electrochemical and Intergranular Corrosion-Resistance Testing of Wrought Aluminium Alloys. In C. Chesonis (Ed.), Light Metals 2019. The Minerals, Metals & Materials Series (pp. 331-339). Springer, Cham. DOI:

Kevorkijan, V. M., Hmelak, B., Cvahte, P., Hmelak, S., Dragojević, V., Kovačec, U., Jelen, M., & Volšak, D. (2017). Algorithm for Finding the Correlation Between the Properties of Wrought Aluminum Alloys, the Chemical Composition and the Processing Parameters. In A. Ratvik (Ed.), Light Metals 2017. The Minerals, Metals & Materials Series (pp. 259-263). Springer, Cham. DOI:

Kochetov, Y., Levanova, T., Alekseeva, E., & Loresh, M. (2005). Large neighborhood local search for the p-median problem. Yugoslav Journal of Operations Research, 15(1), 53-63. DOI:

MacQueen, J. B. (1967). Some Methods for Classification and Analysis of Multivariate Observations. In Proceedings of the 5th Berkley Symposium on Mathematical Statistics and Probability, 1, 281-297. http://projecteuclid.org/euclid.bsmsp/1200512992

Rozhnov, I. P., Kazakovtsev, L. A., & Karaseva, M. V. (2021). Informative Features Selection for Building an Optimization Model of the Aluminum Electrolytic Cell Thermal Regime. Revista geintec-gestao inovacao e tecnologias, 11(4), 605-622. DOI:

Rozhnov, I. P., Orlov, V. I., & Kazakovtsev, L. A. (2018). Increase in Accuracy of the Solution of the Problem of Identification of Production Batches of Semiconductor Devices. 14th International Scientific-Technical Conference on Actual Problems of Electronic Instrument Engineering, 363-367.

Rozhnov, I. P., Orlov, V. I., & Kazakovtsev, L. A. (2019). VNS-based algorithms for the centroid-based clustering problem. Facta Universitatis. Series Mathematics and Informatics, 34(5), 957-972. DOI:

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License

About this article

Publication Date

27 February 2023

Article Doi

eBook ISBN

978-1-80296-960-3

Publisher

European Publisher

Volume

1

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-403

Subjects

Hybrid methods, modeling and optimization, complex systems, mathematical models, data mining, computational intelligence

Cite this article as:

Rozhnov, I. P., Kazakovtsev, L. A., & Masich, I. S. (2023). Determination of Homogeneous Batches of Anodes Based on Hybrid Optimization Models. In P. Stanimorovic, A. A. Stupina, E. Semenkin, & I. V. Kovalev (Eds.), Hybrid Methods of Modeling and Optimization in Complex Systems, vol 1. European Proceedings of Computers and Technology (pp. 94-101). European Publisher. https://doi.org/10.15405/epct.23021.12